Roofing Plywood Thickness: Choosing the Right Foundation for Roof

Selecting the appropriate plywood thickness for your roof is not just a choice; it’s a pivotal decision that directly influences […]

Selecting the appropriate plywood thickness for your roof is not just a choice; it’s a pivotal decision that directly influences the stability and durability of your entire roofing structure. The plywood you choose serves as the foundation, ensuring resilience against various environmental elements.

In this article, I will provide important factors that influence the choice of roofing plywood thickness, empowering you to make an informed decision that will safeguard your investment for years to come.

You may also like:

Understanding Roofing Plywood Thickness

Plywood is a versatile material widely used in construction and woodworking projects, known for its strength, durability, and ease of use. A key aspect to consider when working with plywood is its thickness, which can vary based on the intended application.

1. Rafter Spacing

Impact on Plywood Thickness

The distance between supporting rafters, termed rafter spacing, is a key factor in determining the ideal plywood thickness. The unique demands of different spacing requirements necessitate varying plywood thickness to provide optimal support.

Guidelines for Different Spacing

- 16 Inches Apart: For roofs with rafters spaced 16 inches apart and minimal snow load, a minimum thickness of 3/8 inch is recommended. This ensures adequate support while considering lighter loads.

- Up to 24 Inches: Most residential roofs with rafter spacing up to 24 inches find suitability with a 1/2-inch plywood thickness. This strikes a balance between structural support and material economy.

- Steeper Pitches or Wider Spacing: Roofs featuring steeper pitches, heavier weight loads, or wider rafter spacing demand a thicker plywood, typically around 5/8 inch. This additional thickness provides the necessary strength to support increased loads and diverse architectural configurations.

2. Roof Pitch

How Roof Slope Affects Plywood Requirements

The angle of your roof, known as roof pitch, plays a pivotal role in determining plywood thickness. The slope of the roof governs how the weight is distributed across the structure, directly impacting the load-bearing capacity of the plywood.

Recommended Thickness for Various Pitch Angles

- Flat Roofs or Metal Coverings: Optimal support for flat roofs or those with metal coverings is achieved with a thickness of 3/4 inch. This ensures the plywood can handle the challenges posed by the lack of slope and the potential extra weight of metal coverings.

- Asphalt Shingle Roofs: For roofs adorned with asphalt shingles and rafter spacing up to 24 inches, a commonly recommended thickness of 1/2 inch suffices. This strikes a balance between the weight of the shingles and the structural demands of the roof.

3. Live Loads

Understanding the Weight of Snow, Rain, and Other Elements

Live loads refer to the external elements’ weight, such as snow and rain, that the roof must bear. Choosing the right plywood thickness involves considering the potential load-bearing requirements imposed by these dynamic factors.

Plywood Thickness Corresponding to Live Loads

- Guidelines for Roofs with Minimal Snow Load: A plywood thickness of 3/8 inch is adequate for roofs experiencing minimal snow loads. This caters to the need for support without unnecessary over-engineering.

- Recommended Thickness for Most Residential Roofs: For the majority of residential roofs, a plywood thickness of 1/2 inch is recommended. This strikes a balance between structural support and material economy, considering typical weather conditions.

- Thicker Plywood for Specific Conditions: In cases of steeper pitches or heavier weight loads, opting for thicker plywood, around 5/8 inch, ensures the structure’s robustness and ability to withstand increased pressures.

4. Dead Loads

Importance of Considering the Weight of Roof Components

Beyond external factors, dead loads, which encompass the weight of the roof itself, significantly influence plywood thickness requirements. The choice of thickness here ensures that the plywood can bear the weight of the entire roofing system.

Plywood Thickness for Different Dead Load Scenarios

- Asphalt Shingle Roofs: Consider a plywood thickness of 1/2 inch for asphalt shingle roofs with rafter spacing up to 24 inches. This thickness strikes a balance between the weight of the shingles and the structural demands of the roof.

- Most Other Roof Types: Opt for thicker plywood, around 5/8 inch, for most other roof types. This added thickness is necessary to support the unique characteristics and heavier materials often associated with diverse roofing configurations.

5. Type of Roof Covering

Varied Requirements Based on Roofing Materials

Different roofing materials come with distinct weight and support requirements. The choice of plywood thickness should align with the specific demands of your selected roof covering, ensuring compatibility and long-term structural integrity.

Plywood Thickness for Different Roof Coverings

- Asphalt Shingle Roofs: Ensure a plywood thickness of 1/2 inch for roofs with asphalt shingles and rafter spacing up to 24 inches. This provides sufficient support for the weight of the shingles without unnecessary bulk.

- Most Other Roof Types: Consider 5/8-inch plywood for most other roof types. This thicker plywood is better equipped to handle the varied demands posed by different roofing materials.

6. General Guide to Plywood Thickness

Minimum Thickness Recommendations

- Minimal Snow Load and 16-Inch Rafter Spacing: A plywood thickness of 3/8 inch is suitable for areas with minimal snow loads and rafter spacing of 16 inches. This ensures structural integrity without excess material.

- Most Residential Roofs (Up to 24 Inches): Opt for a 1/2-inch plywood thickness for most residential roofs, especially when rafter spacing is up to 24 inches. This strikes a balance between structural support and material economy.

- Steeper Pitches, Heavier Weight Loads, or Wider Rafter Spacing: Roofs with steeper pitches, heavier weight loads, or wider rafter spacing benefit from a thicker plywood, typically 5/8 inch. This added thickness caters to increased structural demands.

- Flat Roofs or Roofs with Metal Coverings: A plywood thickness of 3/4 inch is advisable for flat roofs or roofs with metal coverings. This extra thickness provides the necessary strength to support the unique challenges posed by these configurations.

Common Thickness for Different Roof Configurations

- Asphalt Shingle Roofs: A plywood thickness of 1/2 inch is common for asphalt shingle roofs with rafter spacing up to 24 inches. This is a standard choice for balancing support and material efficiency.

- Most Other Roof Types: Opt for 5/8-inch plywood for most other roof types. This common thickness accommodates the diverse demands associated with different roofing materials and configurations.

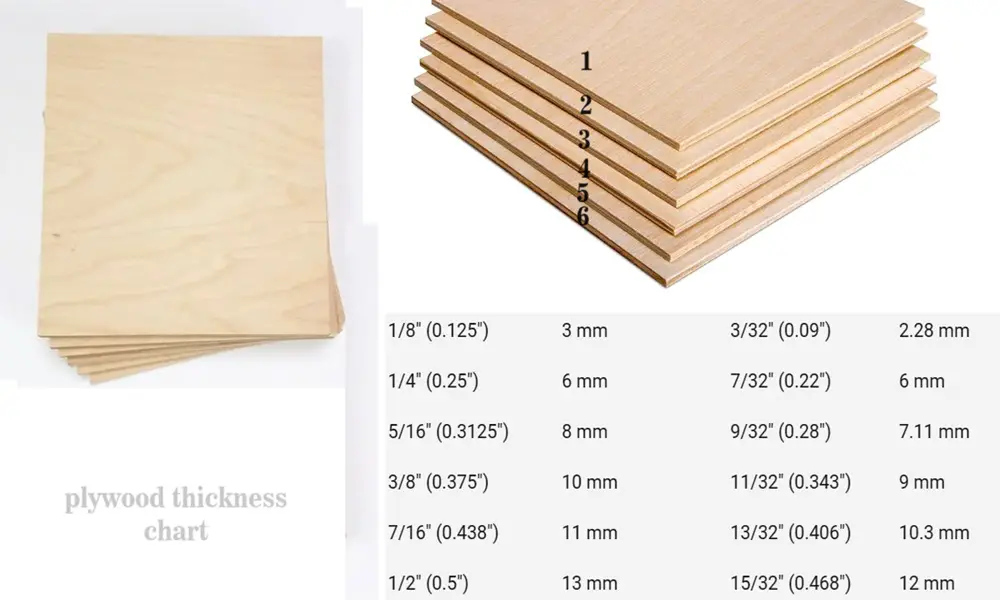

Plywood Thickness Chart

Here is a plywood thickness chart that I created using the information from various existing sources.

| Nominal Thickness (Inches) | Nominal Thickness (mm) | Actual Thickness (Inches) | Actual Thickness (mm) |

| 1/8″ (0.125″) | 3 mm | 3/32″ (0.09″) | 2.28 mm |

| 1/4″ (0.25″) | 6 mm | 7/32″ (0.22″) | 6 mm |

| 5/16″ (0.3125″) | 8 mm | 9/32″ (0.28″) | 7.11 mm |

| 3/8″ (0.375″) | 10 mm | 11/32″ (0.343″) | 9 mm |

| 7/16″ (0.438″) | 11 mm | 13/32″ (0.406″) | 10.3 mm |

| 1/2″ (0.5″) | 13 mm | 15/32″ (0.468″) | 12 mm |

| 5/8″ (0.625″) | 16 mm | 19/32″ (0.593″) | 15 mm |

| 3/4″ (0.75″) | 19 mm | 23/32″ (0.718″) | 18 mm |

| 1-1/8″ (1.13″) | 28 mm | 1-1/8″ (1.13″) | 28 mm |

Understanding Nominal and Actual Thickness

- Nominal Thickness: This is the thickness specified when purchasing plywood. For example, a sheet labeled as 1/2″ plywood should ideally measure 1/2″ in thickness.

- Actual Thickness: The real thickness of the plywood, which may be slightly less than the nominal thickness due to factors like sanding and moisture content. It’s crucial to consider the actual thickness for precise project planning.

Applications of Different Plywood Thicknesses

- 1/8″ (0.125″) – 3 mm:

- Ideal for intricate projects, model-making, and lightweight applications.

- 1/4″ (0.25″) – 6 mm:

- Commonly used for furniture backing, cabinet backs, and lightweight projects.

- 5/16″ (0.3125″) – 8 mm:

- Suitable for cabinet framing and other applications requiring slightly more strength.

- 3/8″ (0.375″) – 10 mm:

- Widely used for cabinet construction, shelves, and other structural components.

- 7/16″ (0.438″) – 11 mm:

- Provides enhanced strength, suitable for subfloors and roofing.

- 1/2″ (0.5″) – 13 mm:

- Versatile thickness for various applications, including furniture, cabinets, and general construction.

- 5/8″ (0.625″) – 16 mm:

- Commonly used for structural framing, sheathing, and heavier-duty applications.

- 3/4″ (0.75″) – 19 mm:

- Standard thickness for many construction applications, including flooring and furniture.

- 1-1/8″ (1.13″) – 28 mm:

- Reserved for heavy-duty structural use, often seen in large-scale construction projects.

Plywood Thickness Recommendations for Various Roof Types

| Roof Type | Rafter Spacing | Minimum Thickness | Recommended Thickness |

|---|---|---|---|

| Low-slope (less than 3:12 pitch) | Any | 3/4 inch (19.1 mm) | 3/4 inch (19.1 mm) |

| Moderate-slope (3:12 to 6:12 pitch) | Up to 24 inches | 1/2 inch (12.7 mm) | 5/8 inch (15.9 mm) |

| Steep-slope (over 6:12 pitch) | Up to 24 inches | 5/8 inch (15.9 mm) | 3/4 inch (19.1 mm) |

Understanding the Recommendations

- Low-slope (less than 3:12 pitch):

- Rafter Spacing: Any

- Minimum Thickness: 3/4 inch (19.1 mm)

- Recommended Thickness: 3/4 inch (19.1 mm)

- Details: For low-slope roofs with minimal pitch, a sturdy 3/4-inch plywood provides the necessary support and durability.

- Moderate-slope (3:12 to 6:12 pitch):

- Rafter Spacing: Up to 24 inches

- Minimum Thickness: 1/2 inch (12.7 mm)

- Recommended Thickness: 5/8 inch (15.9 mm)

- Details: Moderate-slope roofs with pitches ranging from 3:12 to 6:12 can opt for a 1/2-inch minimum thickness, but for enhanced strength, a recommended 5/8-inch thickness is advisable.

- Steep-slope (over 6:12 pitch):

- Rafter Spacing: Up to 24 inches

- Minimum Thickness: 5/8 inch (15.9 mm)

- Recommended Thickness: 3/4 inch (19.1 mm)

- Details: Steep-slope roofs demand increased strength. A minimum thickness of 5/8 inch is recommended, with an optimal choice being 3/4 inch for robust support.

Conclusion

The process of choosing the right plywood thickness for your roof is a critical undertaking. By carefully considering factors such as rafter spacing, roof pitch, live loads, dead loads, and the type of roof covering, you can make an informed decision that ensures a resilient, durable roofing structure capable of withstanding the test of time. Always consult with roofing professionals or structural engineers for specific requirements and exceptional cases.

Related article

Plywood Walls in Garage: Vertical or Horizontal?

Painting Plywood Walls in Garage – A Step-by-Step Guide

Plywood Garage Walls: A Durable and Stylish Solution

Plywood or OSB for Garage Shelves: Which One to Choose?

2×4 and Plywood Garage Shelves