What Size Torsion Spring Do I Need?

What Size Torsion Spring Do I Need Are you in need of a torsion spring but unsure about its size? […]

What Size Torsion Spring Do I Need

Are you in need of a torsion spring but unsure about its size? Choosing the correct torsion spring size is crucial for ensuring optimal performance and safety in various applications.

Whether you’re working on a garage door, a mechanical device, or any other machinery that requires torsion springs, understanding how to determine the right size is essential.

In this article, we will explore the factors influencing torsion spring size, the calculations involved, and other essential considerations. Let’s dive in and find the perfect torsion spring size for your needs!

Understanding Torsion Springs

Before we delve into determining the size of a torsion spring, let’s gain a basic understanding of what torsion springs are and how they function.

Torsion springs are helical springs that apply torque or rotary force when twisted. They store mechanical energy and release it when the torque is released.

These springs are widely used in various applications, such as garage doors, clothespins, and various mechanical systems.

Torsion springs come in different sizes and specifications, depending on the specific application requirements. The size of a torsion spring refers to its dimensions, including the wire diameter, inner and outer diameter, number of coils, and overall length.

Determining the right size is crucial to ensure the spring provides the required torque and fits within the allocated space.

Factors Influencing Torsion Spring Size

When selecting the size of a torsion spring, several factors come into play. Understanding these factors will help you make an informed decision and choose the right spring for your needs. Here are some key factors to consider:

Load Requirements

The load requirements refer to the amount of torque or force the torsion spring needs to handle. Determining the load requirements is crucial to avoid underloading or overloading the spring.

It’s important to consider both the static and dynamic loads that the spring will encounter during operation.

Space Limitations

The available space for installing the torsion spring plays a significant role in determining its size. Measure the available space carefully, taking into account any restrictions or constraints that may affect the size of the spring. Ensure the selected spring size fits within the allocated space without any interference.

Working Environment

The working environment of the torsion spring is an important consideration when determining its size. Factors such as temperature, humidity, corrosive substances, and vibration levels can affect the performance and lifespan of the spring. Choose a spring material and size that can withstand specific environmental conditions.

Required Deflection

required deflection of the torsion spring refers to the amount of twist or rotation the spring needs to provide. It is important to consider the desired deflection angle and the required torque to meet the application’s functional requirements. The deflection capacity of the spring is influenced by its size and material.

Cycle Life

Cycle life refers to the number of times a torsion spring can go through a complete cycle of twisting and untwisting before it experiences fatigue or failure.

Consider the expected usage of the spring and choose a size that can withstand the required number of cycles without compromising its performance or safety.

Material Selection

The material of the torsion spring affects its strength, durability, and resistance to corrosion or other environmental factors.

Different materials, such as stainless steel, music wire, or titanium, have varying properties that should be considered based on the application requirements. Select a material that suits the specific needs of your application.

Calculating the Required Torsion Spring Size

Calculating the required torsion spring size involves considering the application-specific parameters and performing relevant calculations.

While complex mathematical equations exist for precise calculations, a simplified approach can help estimate the spring size. Here are the key steps involved:

Determining the Torque Requirement

Start by determining the torque requirement of your application. This can be done by analyzing the load and the distance from the center of rotation where the force is applied. Calculate the torque in Newton meters (Nm) or other appropriate units.

Considering the Wire Diameter

The wire diameter of the torsion spring affects its strength and flexibility. Thicker wire diameters provide higher torque capacity but may limit the spring’s ability to fit within tight spaces.

Consider the available space and the desired torque to select an appropriate wire diameter.

Assessing the Spring Length

The overall length of the torsion spring impacts its deflection capacity. Longer springs allow for greater deflection but may require more space. Measure the available space and consider the desired deflection to determine the appropriate spring length.

Evaluating the Number of Coils

The number of coils in a torsion spring affects its stiffness and torque capacity. More coils generally result in higher torque capacity but may limit the deflection range. Calculate the number of coils based on the desired torque and deflection requirements.

Examining the Spring Material

The material selection for the torsion spring should be based on the application requirements, including environmental factors and load conditions. Consider the material’s strength, durability, corrosion resistance, and other relevant properties.

Determining the Torque Requirement

To determine the torque requirement of your application, you need to consider the force or load that the torsion spring needs to counteract. This can be done by analyzing the specific requirements of your application and calculating the torque. Here’s a simplified approach to estimating the torque requirement:

- Identify the force or load that needs to be balanced or counteracted by the torsion spring.

- Determine the distance from the center of rotation where the force is applied.

- Calculate the torque by multiplying the force by the distance.

It’s important to consider both the static and dynamic loads to ensure the torsion spring can handle the required torque throughout its operational cycle.

Considering the Wire Diameter

The wire diameter of a torsion spring affects its strength, flexibility, and torque capacity. Thicker wire diameters provide higher torque capacity but may limit the spring’s ability to fit within tight spaces. On the other hand, thinner wire diameters offer greater flexibility but may have lower torque capacity.

When selecting the wire diameter, consider the available space for installation, the torque requirement, and

the desired deflection. A general guideline is to choose a wire diameter that allows for sufficient strength to handle the torque while still fitting within the allocated space.

Assessing the Spring Length

The overall length of the torsion spring plays a crucial role in its deflection capacity. Longer springs allow for greater deflection, while shorter springs offer limited deflection. Measure the available space and consider the desired deflection angle to determine the appropriate spring length.

It’s important to ensure that the selected spring length allows for the required deflection without exceeding the available space or causing any interference with other components or structures.

Evaluating the Number of Coils

The number of coils in a torsion spring impacts its stiffness and torque capacity. More coils generally result in a higher torque capacity but may limit the deflection range. Conversely, fewer coils offer greater deflection but may have lower torque capacity.

Calculate the number of coils based on the desired torque and deflection requirements. Consider the available space, the wire diameter, and the desired spring length. It’s crucial to strike a balance between torque capacity and deflection to ensure optimal performance.

Examining the Spring Material

The choice of material for the torsion spring is vital for its performance and durability. Different materials possess varying properties that can affect factors such as strength, corrosion resistance, and temperature tolerance. Common materials used for torsion springs include stainless steel, music wire, and various alloys.

Consider the environmental conditions in which the spring will operate, such as temperature, humidity, and exposure to corrosive substances. Select a material that is suitable for the specific application requirements to ensure the longevity and reliability of the torsion spring.

Understanding the Working Environment

The working environment of the torsion spring has a significant impact on its performance and lifespan. Factors such as temperature fluctuations, humidity, corrosive substances, and vibration levels can affect the spring’s material properties and overall functionality.

Ensure that the selected torsion spring size and material can withstand the specific environmental conditions it will be exposed to.

Consult with experts or refer to manufacturer guidelines for recommendations on materials and coatings that offer enhanced resistance to the working environment.

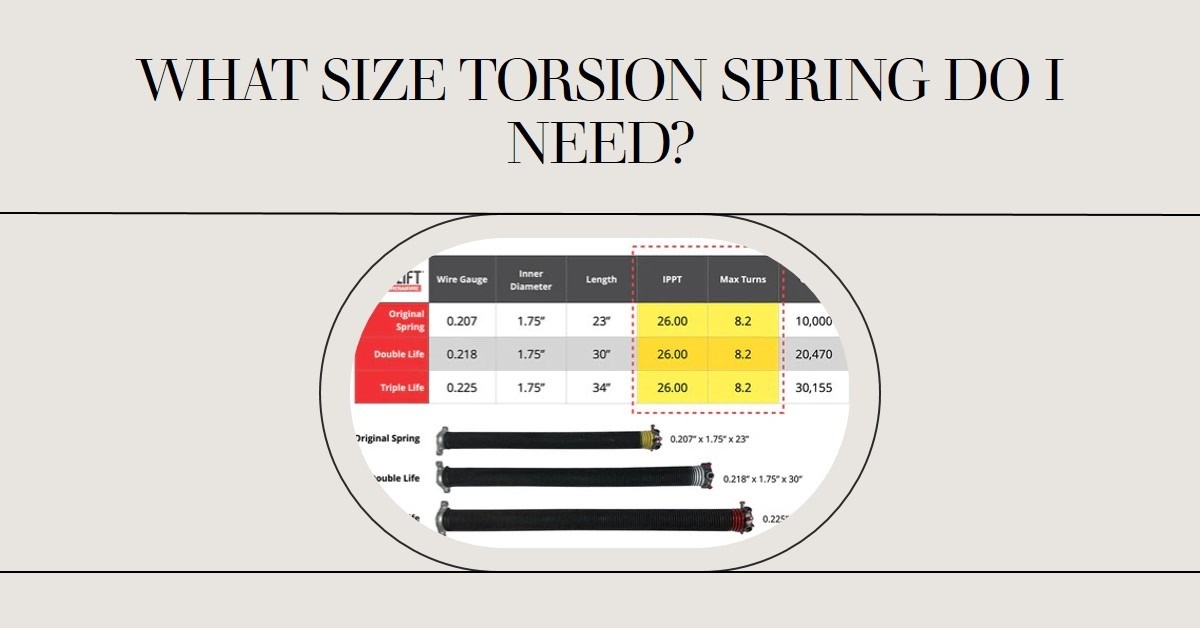

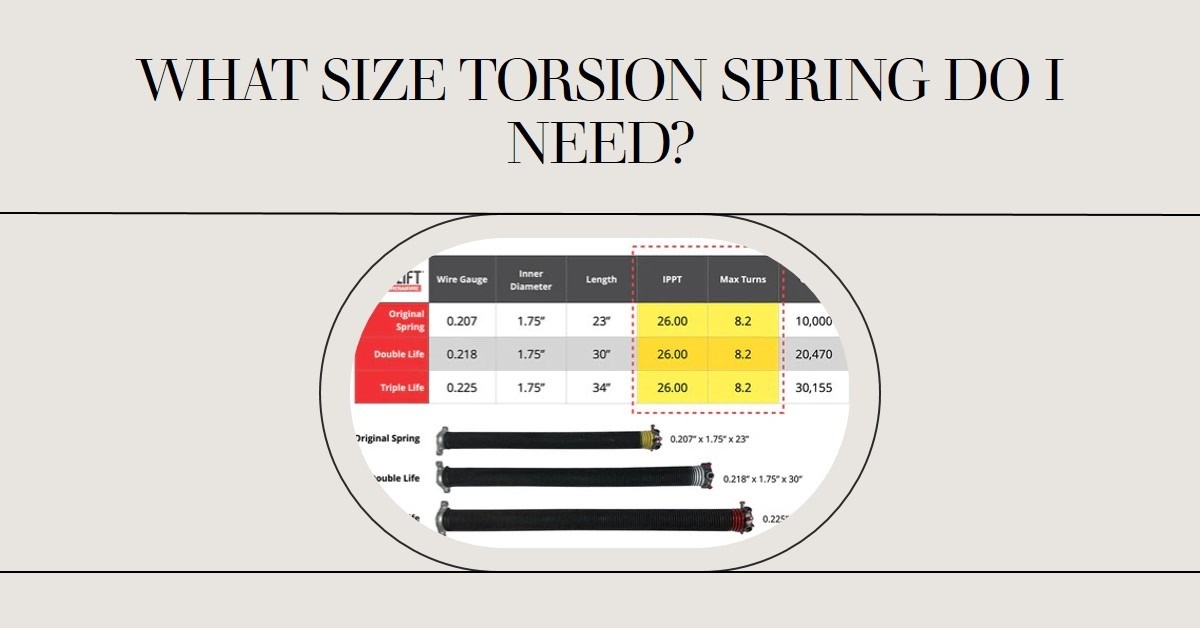

Consulting Spring Manufacturer’s Guidelines

When determining the size of a torsion spring, it’s beneficial to consult the guidelines provided by spring manufacturers.

Manufacturers often provide detailed information on selecting the appropriate spring size based on specific parameters and application requirements.

Refer to the manufacturer’s catalog, technical data sheets, or online resources to gain insights into the recommended spring sizes for different load capacities, deflection requirements, and environmental conditions. This information can serve as a valuable reference point in your decision-making process.

Common Mistakes to Avoid

When determining the size of a torsion spring, it’s important to be aware of common mistakes that can lead to improper selection and suboptimal performance. Here are a few mistakes to avoid:

- Neglecting to consider the specific application requirements and load conditions.

- Overlooking the available space for installation, resulting in size limitations or interference.

- Underestimating the required deflection or torque, leading to inadequate spring performance.

- Choosing an unsuitable material that is not compatible with the working environment.

- Failing to consult manufacturer guidelines or seeking expert advice when needed.

By avoiding these common mistakes, you can ensure that the selected torsion spring size is appropriate for your application, maximizing performance and longevity.

Choosing the Right Torsion Spring Supplier

When it comes to sourcing torsion springs, it’s essential to choose a reliable and reputable supplier. Consider the following factors when selecting a torsion spring supplier:

- Experience and Expertise: Look for suppliers with extensive experience and expertise in manufacturing torsion springs.

- Quality Assurance: Ensure that the supplier has stringent quality control measures in place to deliver high-quality torsion springs that meet industry standards.

- Customization Options: Check if the supplier offers customization options, such as different sizes, materials, and finishes, to cater to your specific requirements.

- Timely Delivery: Choose a supplier known for their prompt and reliable delivery service, ensuring that you receive your torsion springs on time.

- Competitive Pricing: Compare prices from different suppliers to ensure you’re getting the best value for your investment without compromising on quality.

- Customer Reviews and Feedback: Read customer reviews and feedback to gauge the supplier’s reputation and customer satisfaction level.

- Support and Assistance: Opt for a supplier that provides excellent customer support and assistance, helping you choose the right torsion spring size and addressing any concerns or queries you may have.

Conclusion

Selecting the right size for a torsion spring is crucial for optimal performance and safety in various applications. By considering factors such as load requirements, space limitations, working environment, deflection needs, and consulting manufacturer guidelines, you can determine the appropriate torsion spring size.

Remember to calculate the torque requirement, consider the wire diameter, assess the spring length and number of coils, and choose a suitable material. Avoid common mistakes and select a reputable torsion spring supplier to ensure high-quality and reliable springs for your application.

By understanding the intricacies of torsion spring sizing and following the guidelines outlined in this article, you can confidently determine the perfect torsion spring size for your specific needs.

More about springs

OMI 2.0 Torsion Spring: The Advancements in Garage Door Springs

Winding Garage Door Springs: The Ultimate Guide

How to Measure Garage Door Torsion Springs: A Complete Guide

What Size Torsion Spring for 16×7 Garage Door

Is Replacing a Garage Door Spring Dangerous?