Concrete Pitting Solutions: Prevention & Repair

Concrete Pitting In this article, I will explore the causes of concrete surface damage, offer techniques for preventing concrete damage, […]

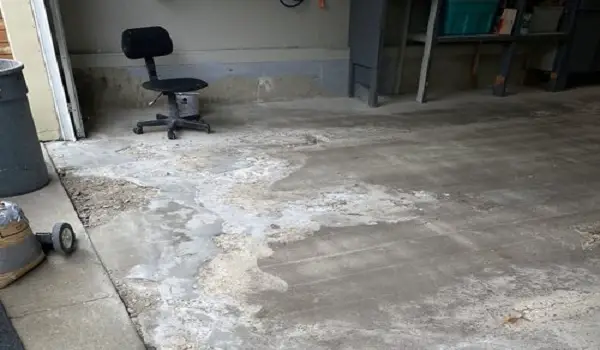

Concrete Pitting

In this article, I will explore the causes of concrete surface damage, offer techniques for preventing concrete damage, and provide effective repair methods for pitted concrete surfaces. Whether you’re dealing with a pitted garage floor or any concrete surface in need of repair, we’ve got you covered!

Concrete pitting can occur due to various factors such as environmental conditions, usage, and lack of maintenance. These factors can lead to unsightly and potentially hazardous conditions that require immediate attention. Fortunately, there are preventive measures you can take to protect your concrete surfaces and effective repair techniques to restore their appearance and integrity.

Understanding Concrete Pitting

In this section, we will take a closer look at concrete pitting and explore the various factors that contribute to concrete surface damage. Understanding the causes of concrete pitting is the first step in preventing and repairing this common issue.

What is Concrete Pitting?

Concrete pitting refers to the formation of small craters or depressions on the surface of concrete. These pits can vary in size and severity, ranging from minor imperfections to deep holes that compromise the structural integrity of the concrete.

Causes of Concrete Pitting

Concrete pitting can be attributed to a combination of environmental factors, usage, and poor maintenance practices. Here are some common causes:

- Freeze-thaw cycles: Repeated cycles of freezing and thawing can cause moisture to expand and contract within the concrete, leading to surface damage.

- Chemical exposure: Harsh chemicals such as salt, acids, and alkalis can erode the concrete surface, resulting in pitting.

- Heavy foot or vehicle traffic: High volumes of traffic can wear down the protective layer of the concrete, making it more susceptible to pitting.

- Poor construction techniques: Inadequate mixing, curing, or finishing during the concrete installation process can contribute to surface defects.

Impact of Concrete Pitting

Concrete pitting not only affects the appearance of the surface but also compromises its durability and functionality. Pitted concrete is more prone to additional damage, such as cracking and spalling, if left untreated. Moreover, it can create safety hazards by uneven surfaces that may cause tripping or accidents.

By understanding the causes of concrete pitting, we can implement effective preventive measures and perform timely repairs to maintain the integrity of our concrete surfaces. In the next sections, we will explore preventive techniques, repair methods, and innovative solutions in more detail.

Preventing Concrete Damage

Preventing concrete damage is crucial for maintaining the longevity and appearance of your concrete surfaces. By implementing regular maintenance routines and protective coatings, you can effectively safeguard against concrete surface deterioration and the formation of pitting.

Maintaining a Cleaning Schedule

Regular cleaning is essential for preventing concrete damage, as it removes dirt, debris, and chemicals that can eat away at the surface over time. Create a cleaning schedule and adhere to it, ensuring that your concrete surfaces are regularly swept, mopped, or pressure-washed.

“Regular cleaning is essential for preventing concrete damage, as it removes dirt, debris, and chemicals that can eat away at the surface over time.”

Sealing the Surface

Another crucial preventive measure is sealing the concrete surface. Applying a high-quality concrete sealer creates a protective barrier that shields the concrete from moisture, chemicals, and other environmental factors that can cause damage. Regularly reapplying the sealer is recommended to maintain its effectiveness.

Implementing Proper Drainage Systems

Water accumulation is a leading cause of concrete surface deterioration. Implementing proper drainage systems, such as sloping the surface away from buildings or installing drain tiles, helps prevent water from pooling and seeping into the concrete. This proactive step minimizes the risk of pitting and other forms of damage.

Table: Comparison of Concrete Coatings

| Coating Type | Advantages | Disadvantages |

|---|---|---|

| Acrylic | Fairly affordable and provides good UV protection | May require regular reapplication |

| Epoxies | Extremely durable and resistant to chemicals and abrasions | Can yellow over time and may require professional application |

| Polyurethanes | Excellent UV resistance and high gloss finish | Costlier compared to other coatings and may require recoating |

By following these preventive measures, you can significantly reduce the likelihood of concrete damage and maintain the longevity of your concrete surfaces. Regular cleaning, sealing, and proper drainage systems are key to preventing concrete surface deterioration and the formation of unsightly pitting.

Choosing the Right Concrete Sealers

Concrete sealers play a vital role in protecting your concrete surface from pitting and damage. With various types available in the market, it’s important to choose the right sealer that suits your specific needs and requirements.

There are three main types of concrete sealers: acrylics, epoxies, and polyurethanes. Each sealer offers unique characteristics and benefits for concrete surface protection.

Acrylic Sealers

Acrylic sealers are popular due to their affordability and ease of application. They provide a glossy finish and offer good resistance to UV rays, water, and chemicals. However, they may not be as durable as other sealers and may require reapplication more frequently.

Epoxies

Epoxies are known for their exceptional durability and strength. They create a tough, chemical-resistant coating that can withstand heavy traffic and protect against various substances such as oils, greases, and solvents. Epoxies are an excellent choice for high-traffic areas and industrial environments.

Polyurethanes

Polyurethane sealers are highly durable and provide excellent protection against abrasion, chemicals, and UV rays. They offer a glossy finish and are more flexible than epoxies, making them ideal for surfaces that are subject to movement or temperature changes. Polyurethanes are commonly used for outdoor applications.

When choosing the right concrete sealer, it’s essential to consider factors such as the intended use of the surface, the level of protection required, and your budget. Consulting with a concrete professional can help you determine the best sealer for your specific needs.

| Sealer Type | Pros | Cons |

|---|---|---|

| Acrylic Sealers | Affordable | May require frequent reapplication |

| Epoxies | Durable and strong | More expensive |

| Polyurethanes | Excellent durability and flexibility | Higher cost |

By choosing the right concrete sealer, you can ensure long-lasting protection for your concrete surface, preventing pitting and maintaining its aesthetic appeal.

Repairing Pitted Concrete: Assessing the Damage

When dealing with pitted concrete surfaces, it is important to assess the extent of the damage before initiating any repair work. This will help determine the appropriate repair techniques and materials needed to restore the concrete’s integrity. In this section, we will provide insights into different techniques for evaluating concrete damage, including visual inspection, tapping, and moisture testing.

Visual Inspection

Visual inspection is the first step in assessing the damage caused by concrete pitting. By carefully examining the surface, you can identify the areas affected by pits and determine the severity of the damage. Look for cracks, holes, or areas where the top layer of concrete has deteriorated.

“Visual inspection allows you to get a closer look at the concrete surface and helps in understanding the underlying causes of pitting.”

Tapping Test

Another technique for assessing concrete damage is the tapping test. To perform this test, gently tap the surface of the concrete with a hammer or similar tool. Pay attention to the sound produced. If you hear a hollow, echoing sound, it indicates that the concrete has become loose or deteriorated. This suggests the presence of pitting and may require further repair.

Moisture Testing

Moisture testing is an essential step in evaluating concrete damage. Excess moisture can contribute to the deterioration of the concrete surface and lead to pitting. To perform a moisture test, tape a plastic sheet to the surface of the concrete and leave it overnight. If moisture appears on the underside of the plastic sheet in the morning, it indicates the presence of moisture and potential damage.

By employing these assessment techniques, you can gain valuable insights into the extent of concrete pitting and its underlying causes. This knowledge will guide you in selecting the most suitable concrete repair techniques and materials to effectively restore and protect your concrete surfaces.

| Assessment Technique | Description |

|---|---|

| Visual Inspection | Examine the surface for cracks, holes, and deterioration to determine the severity of the damage. |

| Tapping Test | Gently tap the surface with a hammer and listen for a hollow, echoing sound, indicating loose or deteriorated concrete. |

| Moisture Testing | Tape a plastic sheet to the surface overnight to check for the presence of moisture, indicating potential damage. |

Resurfacing Techniques: Filling in Concrete Pits

When it comes to repairing pitted concrete surfaces, resurfacing techniques such as patching and filling can be highly effective. These methods help restore the integrity of the concrete by addressing the damaged areas and providing a smooth and even finish.

Step 1: Surface Preparation

Before applying any repair materials, it is crucial to properly prepare the concrete surface. Start by thoroughly cleaning the area to remove any dirt, debris, or loose particles. Use a wire brush or a pressure washer to ensure a clean and sound substrate.

Step 2: Selecting the Right Repair Materials

To fill in the concrete pits, you’ll need to choose the appropriate repair materials. Epoxy-based patching compounds are commonly used for this purpose. These compounds are easy to apply, durable, and provide excellent adhesion to the existing concrete.

Step 3: Applying the Repair Materials

Follow the manufacturer’s instructions for mixing the patching compound. Use a trowel or putty knife to apply the compound to the pitted areas, filling them in completely. Ensure that the compound is applied evenly and leveled with the surrounding surface.

Step 4: Smoothing and Finishing

After applying the repair materials, use a trowel or a float to smooth and level the patched areas. This will help achieve a seamless look and ensure that the repaired surface blends with the rest of the concrete. Allow the repair materials to cure according to the manufacturer’s instructions.

Expert Tip: For larger areas of concrete pitting, consider using a self-leveling resurfacer. This special compound spreads out evenly and can be poured directly onto the damaged surface, producing a smooth and uniform finish.

By following these resurfacing techniques, you can effectively fill in concrete pits and restore the beauty and functionality of your concrete surfaces.

Grinding and Polishing: Smoothing the Surface

In the quest for repairing concrete pitting and achieving a flawless finish, grinding and polishing techniques offer advanced solutions. By employing these methods, you can eliminate pitting and restore a smooth, even surface. Let’s delve into the process and gain insights into the tools and equipment required, as well as the necessary preparation and execution steps.

Step 1: Surface Preparation

Prior to grinding and polishing, it is crucial to prepare the concrete surface adequately. This involves cleaning the area thoroughly, removing any dirt, debris, or loose particles. Additionally, fill in any large gaps or cracks using an appropriate filler material. Once the surface is clean and well-prepared, it is ready for grinding and polishing.

Step 2: Grinding

To start the grinding process, you will need a concrete grinder equipped with diamond grinding pads. These pads come in different grit sizes, each serving a specific purpose. Begin with a coarse grit to remove any stubborn pitting and imperfections. Gradually progress to finer grits to achieve a smoother finish.

Step 3: Polishing

After completing the grinding phase, it’s time to move on to polishing the concrete surface. This step involves using a series of resin-bonded polishing pads, which gradually refine the finish and enhance its shine. Similar to diamond grinding pads, polishing pads come in varying grit sizes. Start with a coarser grit and progressively work your way towards finer grits for optimal results.

Throughout the grinding and polishing process, it’s crucial to ensure proper dust control. Utilize dust extraction equipment to minimize airborne particles and maintain a clean work environment.

Step 4: Protection and Maintenance

Once the grinding and polishing process is completed, it’s essential to protect the newly restored concrete surface. Apply a high-quality concrete sealer to enhance its longevity and resistance against future pitting. Regular maintenance, such as routine cleaning and reapplication of protective coatings, will help keep the surface in optimal condition.

By applying grinding and polishing techniques, you can effectively eradicate pitting from concrete surfaces and achieve a smooth, visually appealing finish.

| Benefits of Grinding and Polishing | Tools Required |

|---|---|

|

|

Applying Coatings: Enhancing Protection

Protective coatings are an essential addition in the fight against concrete pitting. By applying suitable coatings, such as epoxy, polyaspartic, or polyurea, you can give your concrete surface the extra defense it needs to withstand harsh conditions and prevent damage. These coatings provide a barrier between the concrete and external elements, offering enhanced durability and improved resistance to pitting and other forms of surface deterioration.

Coating Options for Concrete Surface Protection

When it comes to selecting a coating for your concrete surface, you have various options to consider. Let’s explore some of these coatings and their benefits:

- Epoxy: Epoxy coatings are known for their exceptional durability and resistance to chemicals, stains, and abrasions. They form a seamless and high-gloss finish, making them an excellent choice for enhancing the appearance and protection of your concrete surface.

- Polyaspartic: Polyaspartic coatings offer rapid curing times, allowing for quick installation even in temperature-sensitive environments. They provide excellent UV resistance and are highly resistant to chemicals, making them ideal for outdoor applications or areas exposed to harsh chemicals.

- Polyurea: Polyurea coatings offer remarkable durability and flexibility, making them suitable for areas that experience frequent movement or heavy impact. They provide excellent resistance to scratches, abrasions, and chemical spills, ensuring long-lasting protection for your concrete surface.

The choice of coating will depend on factors such as the specific requirements of your concrete surface, the desired level of protection, and the application environment. Consulting with a professional in concrete surface protection can help you determine which coating is best suited for your needs.

Proper Application Process

To ensure optimum protection, it is crucial to follow the correct application process when applying coatings to your concrete surface. Here are some key steps to consider:

- Surface Preparation: The concrete surface should be thoroughly cleaned, free of contaminants, and any existing coatings or loose materials should be removed. Proper surface preparation is crucial for achieving a strong bond between the concrete and the coating.

- Priming: Applying a primer can enhance adhesion and improve the overall performance of the coating. The type of primer used will depend on the specific coating being applied.

- Application: Follow the manufacturer’s instructions for mixing and applying the chosen coating. Pay attention to factors such as temperature, humidity, and drying times to ensure proper curing and adhesion.

- Multiple Layers: Depending on the desired level of protection, it may be necessary to apply multiple layers of the coating. Each layer should be allowed to dry and cure properly before applying the next.

By following these steps and ensuring proper surface preparation, application, and curing, you can maximize the benefits of the protective coatings and enhance the long-term durability and appearance of your concrete surface.

Maintaining a Pitted Garage Floor

Once you have repaired your pitted concrete garage floor, it’s essential to implement regular maintenance practices to preserve its condition and prevent further damage. By following a few simple steps, you can ensure that your garage floor remains sturdy and visually appealing for years to come.

Cleaning:

Regular cleaning is crucial for maintaining a pitted garage floor. Sweep or use a dust mop to remove loose dirt and debris. For stubborn stains or spills, use a mild detergent diluted with water and a soft-bristle brush to scrub the affected area. Rinse thoroughly with clean water to remove any residue. Avoid harsh chemical cleaners that can weaken the concrete surface.

Reapplication of Protective Coatings:

To enhance the protection and durability of your garage floor, consider reapplying a protective coating regularly. Depending on the type of coating used, it may need to be reapplied every 1 to 3 years. Follow the manufacturer’s guidelines for proper application and drying times.

Preventive Measures:

In addition to regular cleaning and coating reapplication, it’s important to reinforce preventive measures to minimize further damage to your garage floor. Place mats or rugs at entry points to trap dirt and prevent abrasions. Avoid dragging heavy objects across the floor, as this can cause pitting and scratches. Use floor protectors on furniture or equipment that may come into direct contact with the concrete surface.

Tip: Consider applying a penetrating sealer to your garage floor. This type of sealer will penetrate deeply into the concrete, providing long-lasting protection against moisture, stains, and abrasions.

Regular maintenance practices:

- Sweep or dust mop the floor regularly to remove loose dirt and debris.

- Clean up spills promptly to prevent staining

- Use a mild detergent diluted with water and a soft-bristle brush to scrub stubborn stains.

- Reapply a protective coating every 1 to 3 years, following the manufacturer’s guidelines.

- Use floor mats or rugs at entry points to trap dirt and prevent abrasions.

- Avoid dragging heavy objects across the garage floor.

- Place floor protectors under furniture or equipment that may come into direct contact with the concrete.

By implementing these maintenance practices, you can prolong the life of your repaired pitted garage floor, keeping it in optimal condition and preserving its aesthetic appeal.

| Maintenance Practice | Frequency |

|---|---|

| Cleaning | Regularly |

| Reapplication of Protective Coatings | Every 1 to 3 years |

| Preventive Measures | Ongoing |

Innovative Solutions for Concrete Pitting

When it comes to tackling concrete pitting, there are innovative solutions and technologies available that can effectively address the problem. These solutions utilize advanced repair techniques and cutting-edge protective coatings to restore the integrity of the concrete surface and prevent further damage. Let’s explore some of these innovative methods:

-

Microtoppings and Overlays

Microtoppings and overlays are emerging repair techniques that offer excellent results in fixing pitted concrete surfaces. These thin overlays are applied to the existing concrete, providing a smooth and durable finish that hides any imperfections. Microtoppings and overlays can be customized with various colors and designs to enhance the aesthetics of the concrete, making them a popular choice for both commercial and residential applications.

-

Cutting-Edge Protective Coatings

Protective coatings play a crucial role in preventing concrete pitting by providing an additional layer of defense against heavy foot traffic, chemical exposure, and other damaging elements. The latest advancements in protective coating technology have led to the development of specialized formulations designed specifically to resist pitting. These coatings offer superior durability, abrasion resistance, and chemical resistance, ensuring long-lasting protection for concrete surfaces.

By utilizing these innovative solutions, you can effectively repair pitted concrete and safeguard it from future damage. Whether you choose microtoppings, overlays, or cutting-edge protective coatings, it is important to consult with a professional to determine the most suitable option for your specific needs.

| Solution | Benefits |

|---|---|

| Microtoppings and Overlays |

|

| Cutting-Edge Protective Coatings |

|

Conclusion

In conclusion, maintaining concrete surfaces and preventing concrete pitting is essential for long-lasting durability and aesthetic appeal. By implementing proactive maintenance practices, such as regular cleaning, sealing, and proper drainage systems, individuals can avoid the damaging effects caused by environmental factors, usage, and neglect.

When concrete damage does occur, it is crucial to assess the extent of pitting accurately. Depending on the severity, repairing techniques like resurfacing, grinding, and polishing can restore the integrity of the surface and eliminate pitting. Furthermore, the application of protective coatings, such as epoxy, polyaspartic, and polyurea, provides an added layer of protection against future damage.

As technology advances, innovative solutions like microtoppings and overlays offer alternative methods for addressing concrete pitting. Additionally, cutting-edge protective coatings have been formulated to resist heavy foot traffic and chemical exposure, ensuring even higher levels of durability and surface protection.

By taking action and implementing these maintenance and repair strategies, individuals can save time and money in the long run, preserving their concrete surfaces for years to come. Whether it’s a garage floor or an outdoor pavement, prioritizing preventive measures and utilizing effective repair techniques will contribute to the overall longevity and visual appeal of concrete surfaces.

FAQ

What is concrete pitting?

Concrete pitting refers to the formation of small holes, depressions, or craters on a concrete surface. It is often caused by factors such as environmental conditions, chemical exposure, and wear and tear over time.

What are the causes of concrete pitting?

Concrete pitting can be caused by various factors, including freeze-thaw cycles, salt and chemical exposure, abrasion from heavy usage or vehicle traffic, and poor surface preparation during installation.

How can I prevent concrete damage?

To prevent concrete damage and pitting, it is crucial to implement preventive measures such as regular cleaning, sealing the surface with a protective coating, ensuring proper drainage, and avoiding harsh chemicals or deicers that can deteriorate the concrete.

What are the different types of concrete sealers?

There are various types of concrete sealers available, including acrylic sealers, epoxy sealers, and polyurethane sealers. Each sealer has different properties and is suitable for specific applications. It is important to choose the right sealer based on factors such as the level of protection required and the desired aesthetic finish.

How do I assess pitted concrete for repair?

Assessing pitted concrete for repair involves visually inspecting the surface for the extent of damage, tapping the concrete with a hammer to assess the soundness, and conducting moisture tests to determine if water infiltration is contributing to the pitting.

What are the techniques for repairing pitted concrete?

There are multiple techniques for repairing pitted concrete, including patching and filling. These techniques involve preparing the surface, selecting the appropriate repair materials, and carefully applying them to fill in the pits and restore the integrity of the concrete.

How can grinding and polishing help with pitted concrete?

Grinding and polishing techniques can be used to remove surface imperfections, including pitting, and achieve a smooth, even finish. These techniques involve using specialized equipment and abrasives to restore the surface and enhance its appearance.

What are some effective coatings for concrete surface protection?

When it comes to protecting concrete surfaces from further damage, epoxy, polyaspartic, and polyurea coatings are commonly used. These coatings provide a barrier against chemicals, abrasion, and impact, enhancing the durability and longevity of the concrete surface.

How do I maintain a pitted garage floor?

Proper maintenance of a pitted garage floor includes regular cleaning to remove dirt and debris, reapplication of protective coatings as needed, and implementing preventive measures, such as avoiding dragging heavy objects and using floor mats to minimize wear and tear.

Are there innovative solutions for addressing concrete pitting?

Yes, there are innovative solutions available, such as microtoppings and overlays, which can be applied to the surface to repair pitting. Additionally, there are advanced protective coatings formulated to withstand heavy foot traffic or chemical exposure, providing long-lasting protection against pitting and surface damage.