Unveiling Polyaspartic Garage Floor Problems

Polyaspartic Garage Floor Problems In recent years, polyaspartic garage floor coatings have gained immense popularity for their durability, chemical resistance, […]

Polyaspartic Garage Floor Problems

In recent years, polyaspartic garage floor coatings have gained immense popularity for their durability, chemical resistance, and quick curing time.

Homeowners and garage enthusiasts often opt for this advanced coating to enhance the appearance and longevity of their garage floors. While polyaspartic coatings undoubtedly offer numerous advantages, it’s crucial to be aware of potential problems associated with them.

This article, I will investigate common issues reported by users, providing valuable insight to help you make the right decision.

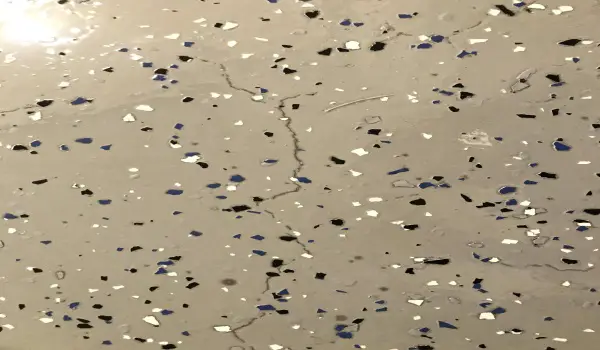

1. Cracking: The Achilles’ Heel of Polyaspartic Coatings

Polyaspartic coatings boast flexibility, but they are not invincible to cracking. Several factors can contribute to this problem, emphasizing the importance of proper installation and ongoing maintenance.

Subtle Foundation Shifts: Even minor movements in the concrete slab can result in cracks in the polyaspartic coating. While the material is designed to adapt to some degree of flexing, prolonged stress from foundational shifts can lead to visible cracks over time.

Heavy Objects Impact: The garage is often a space where heavy tools and equipment are used. Accidental drops or impacts can cause stress fractures in the polyaspartic coating. These fractures may initially be subtle but can evolve into more significant cracks if not addressed promptly.

Improper Installation: The longevity of polyaspartic coatings depends significantly on proper installation. If the concrete substrate is not adequately prepared or the coating is applied incorrectly, the material can become brittle and prone to cracking. Hiring a qualified professional for installation is crucial to mitigate this risk.

2. Yellowing: When UV Resistance Faces the Test of Time

Polyaspartic coatings are known for their UV resistance, but extended exposure to sunlight, particularly in hot climates, can lead to yellowing and fading. This issue is more prevalent with lighter color coatings, where the impact of UV rays is more pronounced. Understanding your garage’s exposure to sunlight is essential in managing and preventing this problem.

3. Slipperiness: A Potential Safety Concern

The smooth finish of polyaspartic coatings, while aesthetically pleasing, can pose a safety concern, especially when wet. Garages are prone to spills, and the slipperiness of polyaspartic coatings may be problematic, particularly for older individuals or those with mobility issues. Incorporating anti-slip additives during the coating process can significantly improve traction and enhance safety.

4. Cost Considerations: Balancing Quality and Budget

While the benefits of polyaspartic coatings are undeniable, it’s essential to acknowledge the higher upfront costs associated with them. In comparison to other garage floor coatings, such as epoxy, polyaspartic coatings demand a more significant financial investment. This cost disparity is attributed to the superior quality of materials used and the expertise required for professional installation.

5. Other Potential Problems: A Holistic View

In addition to the prominent issues mentioned above, users have reported other potential problems with polyaspartic coatings.

Bubbles: Improper mixing of the coating can lead to the formation of air bubbles, leaving imperfections on the finished surface. Ensuring precise mixing during the application process is crucial to achieving a flawless result.

Moisture Issues: If the concrete floor has excessive moisture, the polyaspartic coating may struggle to adhere properly, leading to premature failure. Conducting a moisture test before application is a prudent step to prevent this issue.

Off-Gassing: During installation, polyaspartic coatings can emit a strong odor, necessitating proper ventilation to avoid respiratory irritation. Adequate ventilation is crucial for a safe and comfortable environment during and after the application.

Resources for Further Exploration

For a deeper understanding of the potential problems associated with polyaspartic coatings, consider exploring additional resources:

- 4 Big Problems With Polyaspartic Epoxy Flooring You WILL Experience

- Problems with Polyurea and Polyaspartic Concrete Floor Coatings

Conclusion

While polyaspartic garage floor coatings offer a plethora of benefits, it’s essential to weigh these advantages against potential downsides. Cracking, yellowing, slipperiness, cost considerations, and other issues should be carefully evaluated based on your specific needs and garage environment.

By choosing a qualified contractor for proper installation and following best practices for maintenance, you can maximize the longevity and performance of your polyaspartic garage floor.

It’s crucial to recognize that no flooring solution is entirely problem-free, and the key lies in informed decision-making. Consider the information presented here, explore additional resources, and consult with professionals to determine if a polyaspartic garage floor is the right fit for you.

Expertise and diligence in addressing potential problems will ensure a garage floor that not only looks impressive but also stands the test of time.