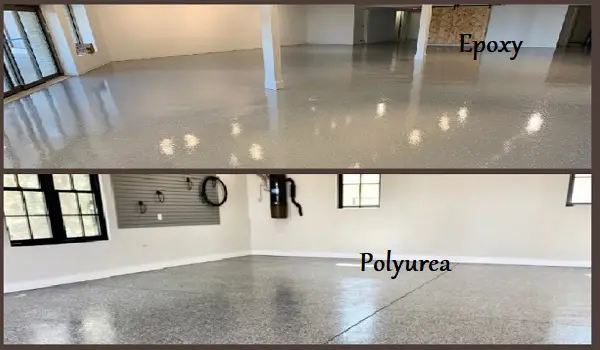

Polyurea vs Epoxy

When it comes to concrete coatings, two popular options stand out: polyurea vs epoxy.

Each of these materials possesses distinct properties and advantages, making them suitable for various applications.

In this article, we will explore the differences between polyurea and epoxy, their unique characteristics, and the best scenarios for their use.

Polyurea vs Epoxy

Polyurea and epoxy are both versatile coatings used to protect and enhance concrete surfaces.

While they share some similarities, they differ significantly in terms of strength, flexibility, chemical and UV resistance, cost, and ease of application.

Understanding these distinctions will help you make an informed decision about which material is best suited for your project.

Read Also: Polyurea Garage Floor Coating

Strength and Durability

Polyurea: 4x Stronger

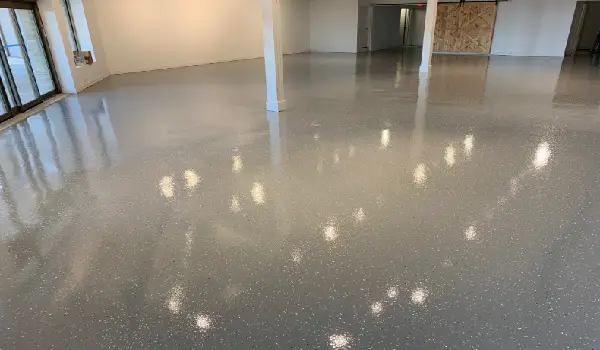

Polyurea boasts exceptional strength, making it a top choice for applications where durability is paramount. Its high tensile strength makes it incredibly resilient, capable of withstanding heavy loads and impacts without cracking or chipping.

This characteristic makes polyurea ideal for areas with high foot traffic, such as garage floors, industrial floors, and pool decks.

Epoxy: 1x Stronger

Epoxy is also strong but falls slightly short in comparison to polyurea. While it may not match the absolute strength of polyurea, epoxy remains a reliable option for many applications, especially in residential settings.

Flexibility

Polyurea: 98% More Flexible

The flexibility of polyurea sets it apart from epoxy. It can elongate significantly without losing its shape, making it highly adaptable to concrete’s natural movements.

This quality is crucial in environments where temperature fluctuations cause concrete to expand and contract. Polyurea’s flexibility also adds to its impact resistance.

Epoxy: 50% More Flexible

Although epoxy is less flexible than polyurea, it still offers satisfactory flexibility for most applications. However, in areas with extreme temperature variations or heavy mechanical stress, polyurea’s superior flexibility may be more advantageous.

Chemical Resistance

Polyurea: More Resistant

Polyurea exhibits remarkable resistance to a wide range of chemicals, including oils, acids, and solvents. This characteristic makes it an excellent choice for locations where spills are common or chemical exposure is likely. In industrial and commercial settings, polyurea’s chemical resistance can prolong the life of the coated surface.

Epoxy: Less Resistant

While epoxy does offer some level of chemical resistance, it falls short compared to polyurea. It may not be suitable for areas where chemical spills are frequent or intense.

UV Resistance

Polyurea: More Resistant

Polyurea is highly resistant to UV radiation, making it ideal for outdoor applications. UV rays can cause coatings to fade, discolor, or deteriorate over time, but polyurea’s UV resistance ensures the coated surface remains vibrant and intact for years.

Epoxy: Less Resistant

Epoxy is somewhat susceptible to UV radiation, and prolonged exposure can cause it to degrade and lose its original appearance.

Cost

Polyurea: More Expensive

The impressive properties of polyurea come at a higher cost compared to epoxy. While it may require a larger initial investment, the long-term benefits may outweigh the expense, especially for high-traffic areas.

- Polyurea: $6-$10 per square foot

Epoxy: Less Expensive

Epoxy is generally more budget-friendly than polyurea, making it an attractive option for projects with cost constraints.

- Epoxy: $3-$7 per square foot

The actual cost will vary depending on the size of the area to be coated, the type of polyurea or epoxy used, and the labor costs in your area.

For example, a single-bay garage floor would typically cost between $1,500 and $3,000 to coat with polyurea, and between $750 and $1,500 to coat with epoxy.

Comparing two materials

| Feature | Polyurea | Epoxy |

|---|---|---|

| Strength | 4x stronger | 1x stronger |

| Flexibility | 98% more flexible | 50% more flexible |

| Chemical resistance | More resistant | Less resistant |

| UV resistance | More resistant | Less resistant |

| Cost | More expensive | Less expensive |

| Application difficulty | More difficult | Easier |

Application Difficulty

Polyurea: More Difficult

Applying polyurea requires specialized equipment and skills, making it a task best suited for professional contractors. The fast curing time of polyurea demands precise and quick application.

Epoxy: Easier

Epoxy application is comparatively simpler, and with proper preparation, it can be a DIY-friendly option for some projects.

Ideal Applications for Polyurea

Polyurea’s outstanding strength, flexibility, and chemical and UV resistance make it an ideal choice for:

- Garage floors

- Industrial floors

- Pool decks

- Commercial facilities

- High-traffic areas

Ideal Applications for Epoxy

Epoxy’s affordability and ease of application make it suitable for:

- Residential floors

- Countertops

- Low-traffic areas

Read Also: Resurface Pitted Garage Floor

Additional Considerations

Curing Time

Polyurea cures rapidly, often within hours, whereas epoxy can take several days to fully cure. This makes polyurea a preferred option for projects with time constraints.

Application Process

Polyurea is a single-component system, requiring mixing and application in one step. Epoxy, on the other hand, is a two-component system that necessitates mixing the resin and hardener separately before use.

Stain Resistance

Polyurea’s chemical resistance also extends to stain resistance, making it an excellent choice for spaces prone to spills and stains.

Conclusion

In conclusion, both polyurea and epoxy are excellent choices for concrete coatings, but they excel in different aspects.

If you prioritize strength, flexibility, chemical resistance, and UV protection, polyurea is the superior option for applications like garage and industrial floors.

If budget and ease of application are more critical, epoxy is a practical choice for residential floors and countertops. Consider your specific needs and the characteristics of each material before making a decision.

FAQs

Is polyurea more expensive than epoxy?

Yes, polyurea generally comes at a higher cost compared to epoxy due to its superior properties.

Can I apply epoxy myself for small projects?

Yes, epoxy can be applied by homeowners for smaller projects with proper preparation and following instructions.

Does polyurea require a professional application?

Yes, due to its fast curing time and specific equipment requirements, polyurea is best applied by professional contractors.

Can I use epoxy on a pool deck?

While epoxy can be used on a pool deck, polyurea’s superior properties make it a better choice for this application.

Few steps to help you find the right professional for your project:

- Online Search: You can start by performing an online search using keywords like “Pittsburgh Polyurea garage floor coatings” or similar phrases. This will likely yield a list of contractors in your area who offer these services.

- Local Directories: Check local business directories, such as Yellow Pages or Yelp, for listings of contractors specializing in garage floor coatings. These platforms often include customer reviews and ratings to help you make an informed decision.

- Ask for Recommendations: Reach out to friends, family, or neighbors who may have recently had their garage floors coated with Polyurea. Personal recommendations can be valuable in finding a reputable contractor.

- Contact Multiple Contractors: Once you’ve compiled a list of potential contractors, contact them individually. Inquire about their experience, request references, and ask for a quote. Be sure to discuss your specific requirements and expectations.

- Check Credentials: Ensure that the contractor is licensed, bonded, and insured. This will help protect you in case of any unforeseen issues during the project.

- Compare Quotes: Don’t forget to compare quotes from different contractors. Consider not only the cost but also the quality of materials and workmanship offered.

- Visit Completed Projects: If possible, visit some of the contractor’s completed projects to assess the quality of their work firsthand.

By following these steps, you should be able to identify a reputable contractor in the Pittsburgh area who can provide Polyurea Coatings for your garage floor. Remember to take your time, do your research, and choose the contractor that best fits your needs and budget.

I hope this helps, and I wish you the best of luck with your garage floor coating project!

Can you locate a contractor in the Pittsburgh area that uses Polyurea Coatings for garage floors?

Thank you for your question. While I don’t have direct access to specific contractors in your area, I can suggest several options to help you find the right professional for your project:

Our suggestions pittsburghepoxy.com and pittsburghgarage.com

When using this directory, be sure to follow the steps mentioned in our previous response to find the right contractor for your specific project.