The Best Epoxy Garage Floor Colors for Your Needs

Epoxy Garage Floor Colors Epoxy garage floor coatings are a popular choice for homeowners who want a durable, low-maintenance, and […]

Epoxy Garage Floor Colors

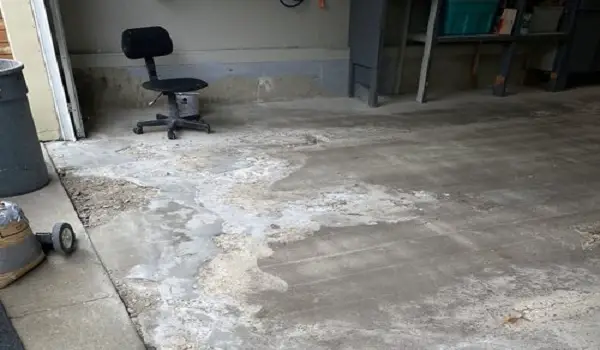

Epoxy garage floor coatings are a popular choice for homeowners who want a durable, low-maintenance, and stylish floor.

There are over 100 different colors available, so you can find the perfect one to match my style.

I was amazed by the wide range of colors at first, but over time I came to understand the nuances of each color and how they can impact the overall ambiance and functionality of my garage space.

In this guide, I will discuss the different garage floor epoxy colors available and help you choose the perfect color for your garage. I will also provide references to some of the most popular epoxy floor coating brands so that you can do more research.

What are Epoxy Garage Floor Colors?

Epoxy garage floor colors refer to the various shades and finishes available for epoxy floor coatings.

Epoxy is a versatile material that can be customized to achieve a wide range of looks, from sleek and modern to classic and rustic.

Whether you want a clean, minimalist appearance or a bold, eye-catching design, epoxy can deliver.

Why choose an epoxy floor for garage?

Epoxy floors are a great choice for garages because they are durable, easy to maintain, and resistant to stains and chemicals. They can also be customized to match your style.

Here are some of the benefits of epoxy floors:

- Durability: Epoxy floors are very strong and can withstand heavy foot and vehicle traffic. They are also resistant to cracking and chipping.

- Easy maintenance: Epoxy floors are easy to clean. You can simply wipe them down with a damp mop.

- Chemical resistance: Epoxy floors are resistant to oil, grease, and other chemicals. This makes them a good choice for garages where there is a lot of spills.

- Customization: Epoxy floors can be customized to match style. You can choose from a variety of colors and finishes.

How to choose the right epoxy garage floor color

When choosing an epoxy garage floor color, there are a few things to keep in mind:

- The size of your garage: If your garage is small, you may want to choose a lighter color to make it feel more spacious.

- The style of your home: You want the color of your garage floor to complement the style of your home. If you have a modern home, you might want to choose a sleek, contemporary color. If you have a traditional home, you might want to choose a more muted color.

- The amount of natural light your garage gets: If your garage doesn’t get much natural light, you may want to choose a brighter color to make it feel more open.

- The type of activities you will be doing in your garage: If you plan on working on cars or other projects in your garage, you may want to choose a color that is easy to clean.

No matter what color you choose, make sure that you love it. After all, you will be seeing it every day.

You may also like:

9 Garage Floor Epoxy Colors: Worldwide Popularity

Let’s explore these widely used epoxy garage floor colors and some have gained worldwide popularity for their stunning visual impact and versatility, and discover why they have become go-to choices for homeowners around the globe.

1. Gray: The Versatile Classic

Gray is a chameleon among epoxy garage floor colors. It effortlessly straddles the line between modern and classic aesthetics.

Its neutral tone complements a variety of design styles, making it a practical choice for garages used for multiple purposes, from parking cars to housing a collection of tools.

Gray also has the remarkable ability to hide dirt and imperfections, maintaining its polished look even in high-traffic areas.

2. Black: Bold and Dramatic

If you’re seeking to make a statement, black is your color of choice. Bold and dramatic, black epoxy floors exude a sense of sophistication and edginess.

Beyond its visual appeal, black is a practical option for garages prone to spills and stains. It effortlessly conceals minor blemishes, maintaining its captivating allure.

3. White: Bright and Airy

For those looking to create a sense of spaciousness, white is the answer. Its bright and airy appearance can make a small garage feel larger and more inviting.

White also excels in garages with abundant natural light, as it maximizes the illumination. It’s a fresh and timeless choice that adds an element of cleanliness and elegance.

4. Blue: Calming Serenity

Blue brings a calming and serene atmosphere to the garage. Its tranquil presence can transform the space into a retreat, perfect for relaxation or contemplation.

Garages located near water or used as leisure spaces benefit from the peaceful vibes that blue exudes. It’s a color that evokes a sense of serenity and balance.

Read more: Blue Epoxy Garage Floors

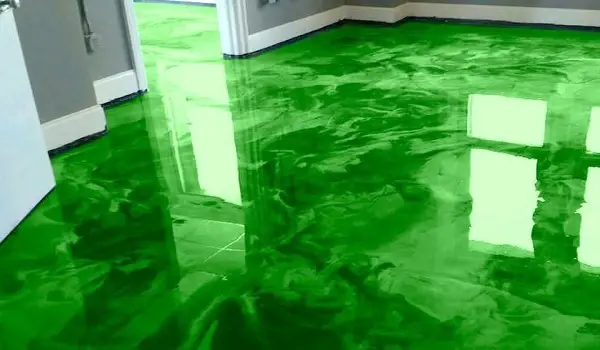

5. Green: Natural Harmony

For those who want to bring a touch of the outdoors inside, green is the ideal choice.

This refreshing and natural color can create a harmonious atmosphere in the garage, making it a suitable canvas for hobbies like gardening or woodworking.

Green epoxy floors connect you with nature while providing an attractive and functional surface.

6. Red: Energetic Passion

Red is all about passion and energy. It’s a color that injects excitement into the garage, making it a perfect fit for spaces used as workshops or hobby rooms.

Red epoxy floors are not for the faint of heart; they demand attention and inspire creativity.

7. Yellow: Cheerful Optimism

If you want to infuse your garage with a dose of cheerfulness and optimism, yellow is your color.

Its vibrant and sunny disposition can brighten up the space, making it a delightful environment for various activities, especially those involving children. Yellow epoxy floors radiate positivity and warmth.

8. Brown: Cozy Comfort

Brown embodies a sense of comfort and coziness. It’s an earthy color that can create a warm and inviting atmosphere in the garage.

Brown epoxy floors work particularly well in garages located within rustic or traditional homes, adding an element of charm and homeliness.

9. Metallic: A Touch of Luxury

For those who desire a touch of luxury and opulence in their garage, metallic epoxy colors like silver, gold, and copper are the answer.

These finishes elevate the space to showroom quality and are perfect for garages used to display prized possessions or vehicles.

Metallic epoxy floors glisten and shine, creating a visually stunning and upscale ambiance.

In the world of epoxy garage floor colors, these shades have gained international acclaim for their beauty and adaptability.

Each color has its own unique charm, and the choice ultimately depends on your personal style, garage’s purpose, and desired ambiance.

With epoxy garage floor coatings, you have the power to transform your garage into a functional, aesthetically pleasing, and personalized space that reflects your individuality. So, here are the 10 brands of epoxy floors that are most widely used today.

10 Most Popular Epoxy Garage Floor Colors

1. Rust-Oleum EPOXYSHIELD Garage Floor Coating

Rust-Oleum EPOXYSHIELD Garage Floor Coating is a two-part epoxy system that’s not only easy to apply but also offers impressive protection.

The first part is the resin, and the second part is the hardener. Mixing them in equal parts and applying them with a roller or brush ensures a tough, durable surface.

This coating stands up to wear and tear, chemicals, and even oil and gasoline, making it a practical choice for any garage.

Coverage: 350 square feet per gallon

Dry time: 12-16 hours

Resistance: Wear and tear, chemicals, oil, and gasoline

Colors: Gray, Tan

2. Rust-Oleum Rocksolid Polycuramine Garage Oil Floor Coating

Rust-Oleum Rocksolid Polycuramine Garage Oil Floor Coating boasts a one-part epoxy formula that simplifies the application process.

Available in an array of stylish colors, this coating is not only resistant to oil, gasoline, and chemicals but also to fading and yellowing. Its quick dry time of 24 hours ensures minimal downtime for your garage.

Coverage: 400 square feet per gallon

Dry time: 24 hours

Resistance: Oil, gasoline, and chemicals

Colors: Gray, modern greige, mocha, dark gray

3. Rust-Oleum EpoxyShield 2-part Gray Gloss Concrete and Garage Floor Paint Kit

The Rust-Oleum EpoxyShield 2-part Gray Gloss Concrete and Garage Floor Paint Kit provides a comprehensive solution for your epoxy flooring needs.

This kit includes epoxy resin, hardener, a roller, and a brush, ensuring that you have all the tools necessary for a successful application. Its gray color option is timeless and versatile, and it offers excellent resistance to wear, chemicals, and more.

Coverage: 400 square feet per gallon

Dry time: 12-16 hours

Resistance: Wear and tear, chemicals, oil, and gasoline

Color: Gray

4. ArmorPoxy Garage Epoxy Floor Kit for Concrete

The ArmorPoxy Garage Epoxy Floor Kit for Concrete is a complete solution for those who seek both functionality and style.

Available in multiple colors, including the vibrant racing blue and classic gray, this kit includes epoxy coating, primer, hardener, roller, and brush. The primer enhances adhesion, ensuring long-lasting results.

Coverage: 500 square feet per gallon

Dry time: 12-16 hours

Resistance: Wear and tear, chemicals, oil, and gasoline

Colors: Gray, racing blue, tan

5. Epoxy Floor Kit – Epoxy-Coat

For budget-conscious homeowners, the Epoxy Floor Kit from Epoxy-Coat offers an attractive solution.

This kit includes a two-part epoxy coating, a roller, and a brush. Available in gray and taupe, it provides reliable protection and style without breaking the bank.

Coverage: 400 square feet per gallon

Dry time: 12-16 hours

Resistance: Wear and tear, chemicals, oil, and gasoline

Colors: Gray, taupe

6. BEHR PREMIUM Slate Gray Self-Priming 1-Part Epoxy Satin

BEHR PREMIUM Slate Gray Self-Priming 1-Part Epoxy Satin is a convenient option for those who prefer a self-priming, one-part epoxy coating.

Drying to a satin finish, it comes in slate gray and silver gray options. This coating is easy to apply and offers impressive resistance to various forms of damage.

Coverage: 500 square feet per gallon

Dry time: 24 hours

Resistance: Wear and tear, chemicals, oil, and gasoline

Colors: Slate gray, silver gray

7. EPODEX® Flooring Epoxy Resin Kit Many Colors Designer Floors

The EPODEX® Flooring Epoxy Resin Kit provides a unique opportunity to customize your garage floor color. This kit includes epoxy resin, hardener, and colorant, with a variety of shades to choose from.

Whether you prefer the classic concrete gray or a metallic finish with satin gray and pearl white, you can create a truly unique floor.

Coverage: Varies by color

Dry time: 24 hours

Resistance: Wear and tear, chemicals, oil, and gasoline

Colors: Concrete gray, metallic kit (satin gray & pearl white)

8. Rust-Oleum RockSolid Metallic Garage Floor Kit

For a touch of flair, the Rust-Oleum RockSolid Metallic Garage Floor Kit offers a metallic finish in colors like silver bullet, brilliant blue metallic, and burnished gold metallic.

This kit includes everything you need for application, ensuring a dazzling result that stands up to wear and chemicals.

Coverage: 400 square feet per gallon

Dry time: 12-16 hours

Resistance: Wear and tear, chemicals, oil, and gasoline

Colors: Silver bullet, brilliant blue metallic, burnished gold metallic

9. Armorpoxy 600 SQ FT Commercial Grade

The Armorpoxy 600 SQ FT Commercial Grade epoxy coating is designed for high-traffic areas. It offers superior durability and resistance to various forms of damage.

Available in a striking blue epoxy color, it’s an excellent choice for those seeking an industrial-grade solution.

Coverage: 600 square feet per gallon

Dry time: 24 hours

Resistance: Wear and tear, chemicals, oil, and gasoline

Color: Blue epoxy

10. Seal-Krete Epoxy-Seal 1-part

Seal-Krete Epoxy-Seal 1-part is designed for sealing concrete floors. It provides protection against moisture and wear and tear. Available in slate gray, this coating helps maintain the integrity of your concrete floor.

Coverage: 500 square feet per gallon

Dry time: 24 hours

Resistance: Moisture and wear and tear

Color: Slate gray

Read Also: How to Paint Garage Floor

How to Prevent Epoxy Garage Floors from Yellowing or Fading

Tips for Preventing Epoxy Garage Floor Yellowing

Epoxy garage floors can develop a yellowish tint over time, primarily due to exposure to UV rays. Drawing from my own experience, I’d like to share some valuable tips to help you keep your epoxy garage floor looking fresh and vibrant:

1. Choose a UV-Resistant Topcoat

One of the most effective ways to prevent your epoxy garage floor from yellowing is by selecting a UV-resistant topcoat.

These topcoats are specifically designed to minimize the impact of UV rays on your floor’s color. When discussing your epoxy floor project with your installer, make sure to inquire about UV inhibitors, which can significantly extend the lifespan of your floor’s color.

2. Regular Cleaning

Maintenance plays a crucial role in preserving your epoxy garage floor’s appearance. By routinely cleaning your floor, you can reduce the risk of discoloration.

Use a gentle cleaner and a soft mop or cloth to remove dirt and debris. Avoid harsh chemicals, as they can damage the epoxy’s protective properties.

Tips for Preventing Epoxy Garage Floor Fading

Fading is another concern for epoxy garage floors, especially when they’re exposed to sunlight and environmental factors. Here are some practical solutions based on my experience to prevent fading:

1. Use Area Rugs or Mats

Placing area rugs or mats strategically in areas with high sun exposure is an excellent way to shield your epoxy floor from the harmful effects of UV rays.

These mats not only protect your floor but also add a layer of comfort to your garage.

2. Apply a Sealant with UV Protection

Consider applying a clear epoxy sealer with UV protection to safeguard your floor against fading. This additional layer of protection acts as a shield, preserving the vibrant color of your epoxy garage floor.

Consult your epoxy flooring professional for recommendations on the best sealant for your specific needs.

Safety Colors for Epoxy Garage Floors

Why Use Safety Colors for Epoxy Garage Floors?

Drawing from my own experience, I understand the importance of safety in a garage, especially if it doubles as a workspace.

Safety colors are a practical and effective way to designate specific areas and hazards, promoting a secure environment.

Common Safety Colors for Epoxy Garage Floors

When considering safety colors for your epoxy garage floor, here are some commonly used options and their meanings:

1. Yellow

Yellow signifies caution and highlights potential hazards. Use this color to draw attention to areas where extra care is needed.

2. Red

Red indicates fire protection equipment or danger zones. It’s crucial to clearly mark these areas to ensure quick and safe access to essential tools or emergency exits.

3. Green

Green designates safe evacuation routes. In case of an emergency, it’s vital to have these routes clearly defined for everyone’s well-being.

Custom Epoxy Garage Floor Colors

How to Get Custom Epoxy Garage Floor Colors

If you have a unique vision for your garage floor, custom epoxy colors can make it a reality. Based on my experience, here’s how you can go about getting the custom epoxy garage floor of your dreams:

1. Consult with a Professional Epoxy Installer

Start by consulting with a professional epoxy installer who has experience in creating custom colors. Share your ideas and vision for your garage floor, and they can guide you through the process.

They will work with you to create a custom color that perfectly suits your style and preferences.

Ideas for Custom Epoxy Garage Floor Colors

Based on my own experience and creativity, here are a couple of exciting ideas for custom epoxy garage floor colors:

1. Metallic Finishes

Add a touch of luxury to your garage by opting for metallic epoxy coatings in various colors. These finishes can create a stunning, almost three-dimensional effect that’s sure to impress.

2. Patterned Designs

Get creative and personalize your garage with patterned designs or even logos using custom-colored epoxy. The possibilities are endless, allowing you to express your unique style.

Read Also: Inexpensive Garage Flooring Ideas

Conclusion

In conclusion, epoxy garage floor colors open up a world of possibilities to elevate both the functionality and aesthetics of your garage space.

Whether your top priorities are durability, style, or safety, rest assured that there’s a perfect epoxy color to cater to your unique needs and preferences.

Taking this knowledge forward, here are some key steps to guide you in choosing the perfect epoxy garage floor color and making the most of your investment:

Next Steps for Choosing the Perfect Epoxy Garage Floor Color

- Evaluate Your Needs: Begin by assessing your specific needs and the purpose of your garage. Are you primarily using it for storage, as a workshop, or as a showcase for your vehicles? Understanding the function of the space will help you narrow down your color options.

- Consider Lighting: Take into account the lighting conditions in your garage. Natural light, as well as the type and placement of artificial lighting, can significantly impact how your epoxy floor color appears. Make sure your choice complements the available light sources.

- Explore Color Samples: Many epoxy flooring professionals offer color samples or swatches. Take advantage of these to see how different colors look in your garage environment. This hands-on approach can help you visualize the end result.

- Consult an Expert: Seek out an experienced epoxy flooring professional who can provide valuable insights and recommendations based on your specific requirements. They can also advise you on the best practices for installation and maintenance.

- Budget Wisely: Set a budget for your epoxy garage floor project. Different colors and finishes may come with varying price points, so it’s essential to strike a balance between your preferences and your budget.

- Samples and Test Areas: If you’re still uncertain about your color choice, consider having a small test area done before committing to the entire garage. This will allow you to see how the color works in your space and make adjustments if needed.

- Maintenance Planning: Depending on your color choice, you may need to adjust your maintenance routine. Lighter colors may require more frequent cleaning to maintain their pristine appearance, while darker colors may hide dirt better but could be more prone to showing scratches.

- Plan for the Long Term: Think about how your color choice will age over time. Will it still be appealing to you in the years to come? Consider the durability and longevity of the color as you make your decision.

- Safety First: If your garage doubles as a workspace, prioritize safety colors where needed. Marking out areas or hazards with safety colors is essential to maintain a secure environment.

- Environmental Impact: Be mindful of the environmental impact of your epoxy flooring choice. Some colors may require more frequent reapplication or touch-ups, which can contribute to waste and additional costs.

By following these steps and consulting with professionals in the field, you can confidently select the perfect epoxy garage floor color that aligns with your needs, style, and preferences.

Your garage is a valuable part of your home, and the right epoxy floor color can truly transform it into a functional and visually appealing space, providing lasting benefits for years to come. Your garage deserves nothing less than the best.

Remember, the best epoxy garage floor color is the one that suits your unique circumstances and personal tastes, so take your time, explore your options, and make an informed choice. Your garage, and by extension, your home, will thank you for it.

What Does Garage-Ready Refrigerator Mean?

Laura Linney

As an expert in the field of garage walls, I have extensive knowledge and experience in enhancing the aesthetic appeal and functionality of these spaces through color and decoration. I specialize in creating visually appealing and practical designs that transform garages into inviting and organized environments.

5Comment

Leave a Reply

You must be logged in to post a comment.

Wow, this is such a helpful guide! I was totally lost on what color to choose for my garage floor, but now I have a few great options. Thanks!

I’m happy to help! Choosing a garage floor color can be tough, so I’m glad I could provide some useful guidance. Did any particular colors from the article catch your eye?

I recently upgraded my garage flooring with epoxy, and I can’t recommend the metallic silver color enough! It adds a modern touch, hides dirt well, and makes the entire space look sleek and clean.

Thank you so much for sharing your experience with the metallic silver epoxy! We’re thrilled to hear that it has added a modern touch to your garage while also providing the practical benefits of hiding dirt and maintaining a clean appearance.

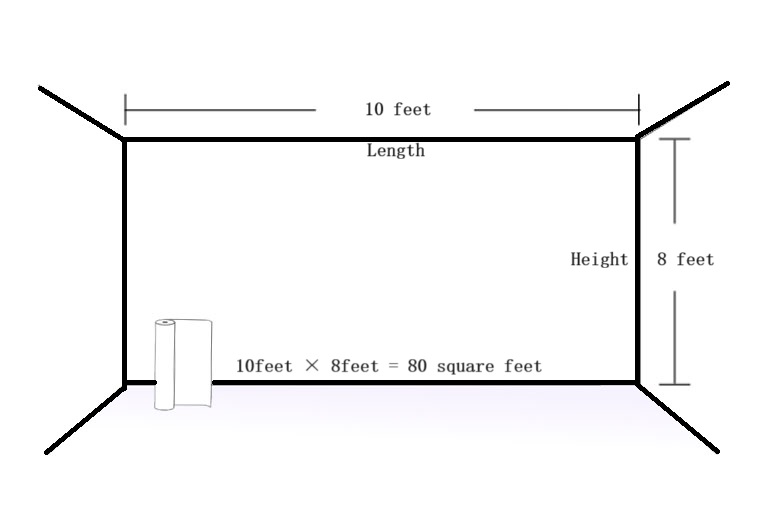

We’re thrilled to hear that our article helped you in making an informed decision about your 10×10 garage door upgrade! Providing valuable insights for our readers is our top priority. Thank you for the thumbs up and best of luck with your garage renovation!